Domestic solid waste treatment is a matter of concern.

In recent years, the increase in population together with socio-economic development has resulted in the demand increase for goods, materials, energy and simultaneously increase in domestic solid waste (DSW) production. The components of the domestic solid waste are increasingly complicated and causing difficulties for the management of DSW in Vietnam.

According to the summary report of the Ministry of Natural Resources and Environment (MONRE), currently, approximate 25.5 million tons of domestic solid wastes are annually produced, of which municipal solid waste (MSW) produces about 38,000 tons/day and rural solid waste produces about 32,000 tons/day. The volume of domestic solid waste generated in municipal areas nationwide annually increases by 10-16% in average. In some municipal areas, the proportion of produced DSW accounts for 90% of the total MSW.

Presently, the popular method of handling domestic waste is landfill (both natural landfill and under-control landfill) leading to land resources waste, environmental pollution at the landfill areas (water source, soil, and air). In addition, a few other methods such as processing into Compost (not so high economic efficiency, easily affected water source), Plasma gasification (low reliability, high cost), etc. have limited capacity.

In order to deal with the above concerns, it is necessary to find out appropriate solutions and technologies to meet the needs of handling the entire solid waste at reasonable prices, ensuring resource-saving, environmental protection and providing high economic benefits.

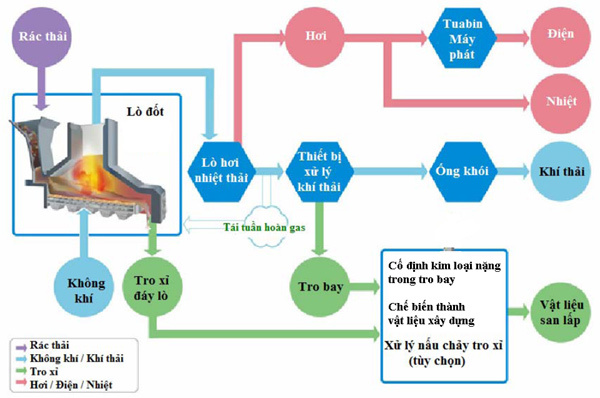

Comprehensive process diagram of waste pile combustion & power generation

PECC1 pioneers in designing waste-to-energy plants.

According to Mr. Hoang Manh Ha, Director of Thermal Power and New Energy Center, PECC1, the waste-to-energy method is one of the most advanced methods and in line with these criteria with the following advantages such as making usage of the available sources, saving natural resources, usage limiting of fossil fuels; This method provides a higher economic efficiency compared to other waste handling methods; Land area used for landfill can be reduced; It hardly gives negative impacts on the environment thank to the strict emission and particulate handling procedures. Ash and slag are used as materials for producing construction materials. Approximate 1000 WTE incinerators are widely developed worldwide: Europe: 30%, Japan: 24%, USA 19% and East Asia 15%.

Typical waste-to-energy plant

Mr. Ha says that WTE technology has been developing for nearby 30 years worldwide and currently it is paid special interest by various investors in Vietnam, especially in big cities with limited land area and complicated domestic solid waste pollution status.

With the experience and quality of consulting services carried out successfully in many power plant projects, PECC1 has been selected and assigned by local and foreign investors to perform important stages in construction and design of present WTE plants such as Project Proposal Report; Supplementary Report on Power Master Planning for WTE projects; Pre-Feasibility Study report; Feasibility Study report; Technical Design, Construction Drawing Design; Review Report and Approval of Basic Design, Technical Design, etc.

In which, projects designed and involved by PECC1 in other important periods such as the most modern WTE plant in Vietnam: Vietstar WTE plant in Cu Chi, Ho Chi Minh City (burning 2,000 tons of domestic waste/day, generating capacity of 40 MW); Southeast Asia's largest WTE plant in Soc Son (burning 4,000 tons of domestic waste/day, generating capacity of 75 MW, started construction in August 2019); Phu Tho WTE plant (burning 1,000 tons of domestic waste, generating capacity of 18MW); Thanh Hoa WTE plant (1,000 tons of domestic waste, generating capacity of 18 MW), hazardous WTE plant in Thai Nguyen; the domestic WTE plants in Hai Phong, Khanh Hoa, etc. When these plants are completed, they will contribute to take advantage of the generated energy source to generate power, effectively treat the increasing amount of waste generated, save land which is previously a landfill area, and reduce environmental pollution.

3D model of the WTE plant without waste separation line before being put into incinerator, designed by PECC1, was started in August 2019, under construction in Soc Son, Hanoi

3D model of the WTE plant with a waste separation line before being put into incinerator, designed by PECC1, was started construction on August 28th, 2019, under construction in Cu Chi, Ho Chi Minh city.

PECC1’s engineers keep being the pioneer in the application of worldwide new, advanced technologies and offering optimum solutions to help projects reach the highest economic efficiency, shorten construction time, and satisfying the safety requirements and increasingly higher required environmental standards.

Along with the development of the country, PECC1 continues to focus on developing high-quality human resources, renewing technological equipment, investing in resources to implement renewable energy power projects such as waste-to-energy, wind power, solar power, etc. in order to provide the best technical services to customers, contribute to the timely supply of electricity for the sake of national construction and development.